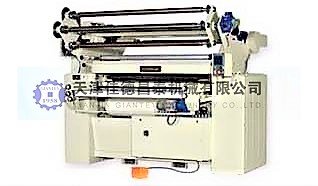

通过式磨革机 GDB-120-T

天津佳德昌泰机械有限公司的新产品GDB-120-T型自动通过式干磨革机用于羊皮皮毛一体的磨革。

该机器是天津佳德昌泰机械有限公司的新开发的产品,整体性能好,具有运行可靠性,本产品改变了往复式磨革带来的皮面留痕问题,是皮毛一体生产厂家制作高档裘皮皮毛一体所需的加工设备。

磨革工作压力通过补偿调节装置随意可调节,以适应磨革辊磨革压力和相应的革板磨量,磨革砂纸更换方便快捷,磨革质量好和效率好。传送带的速度可以调节,并套有海绵体的柔性衬套,以适应各种不同毛长裘皮的加工。在同一革面上可以多次打磨。海绵体衬套更换快捷方便。打磨过程中堆积到革面上的尘屑由刷子将其刷下吸净。

随机成套配备吸尘风机、电控箱和相关安全保护器。

Tianjin Giantey Machinery Co., Ltd.’s new product GDB-120-T automatic pass-through dry leather sanding machine is used for the sanding of sheepskin and fur.

This machine is a newly developed product of Tianjin Giantey Machinery Co., Ltd. It has good overall performance and very high operational reliability. This product has completely changed the problem of leaving marks on the leather surface caused by reciprocating leather grinding. It is an integrated manufacturer of fur The necessary processing equipment is indispensable for the production of high-end fur and fur. It embodies the level of contemporary leather grinding machinery and is the first choice for fur manufacturers to improve product quality.

The working pressure of sanding leather can be adjusted at will through the pedal compensation rocker arm. The leather grinding roller can swing appropriately according to the leather grinding pressure and the requirements of the leather quality. The leather grinding sandpaper is convenient and quick to replace, with high quality and fast working efficiency. The speed of the conveyor belt can be adjusted, and it is covered with a flexible bushing of sponge body to adapt to the processing of various furs. It can be polished multiple times on the same leather surface. The sponge bushing can be replaced quickly and easily. The dust that accumulates on the leather surface during the sanding process is sucked down by the brush.

The machine is equipped with a powerful vacuum fan, electric control box, and related safety protectors.

技术参数表:

| 参数名称Items | 单 位Unit | 数 值Parameter |

| 操作人数Operator | 人Person | 1 |

| 驱动方式Driving style | 气 动Pneumatic | |

| 有效加工宽度Effective working width | 毫 米mm | 1200 |

| 每小时产量Hourly production rate | 张/时Skins/hour | 160-250 |

| 打磨功率Working cylinder power | 千 瓦Kw | 11 |

| 送料功率Feeding power | 千 瓦KW | 0.75 |

| 出料功率Discharging power | 千 瓦KW | 0.37 |

| 吸尘功率Dust-suction power | 千 瓦kW | 3 |

| 作业面积Working area | 米m | 3.09×3.00 |

| 净 重Net weight | 公 斤KG | 1980 |

| 毛 重Gross weight | 公 斤Kg | 2550 |

| 装箱外形尺寸Packing dimensions | 米M | 2.00×1.80×1.73 |

| 体 积Volume | 立方米Cubic M | 5.0 |

| 总 功 率Total power | 千 瓦Kw | 15.12 |